Air cooled liquid chiller - Super low noise acoustic configuration 228 - 867 kW

Air cooled liquid chiller - Super low noise acoustic configuration 228 - 867 kW

Water-cooled industrial liquid chiller bi-frequency version kW 60Hz - 12.4 - 191.7 kW

Air liquid chiller 1.8 - 4.4 kW

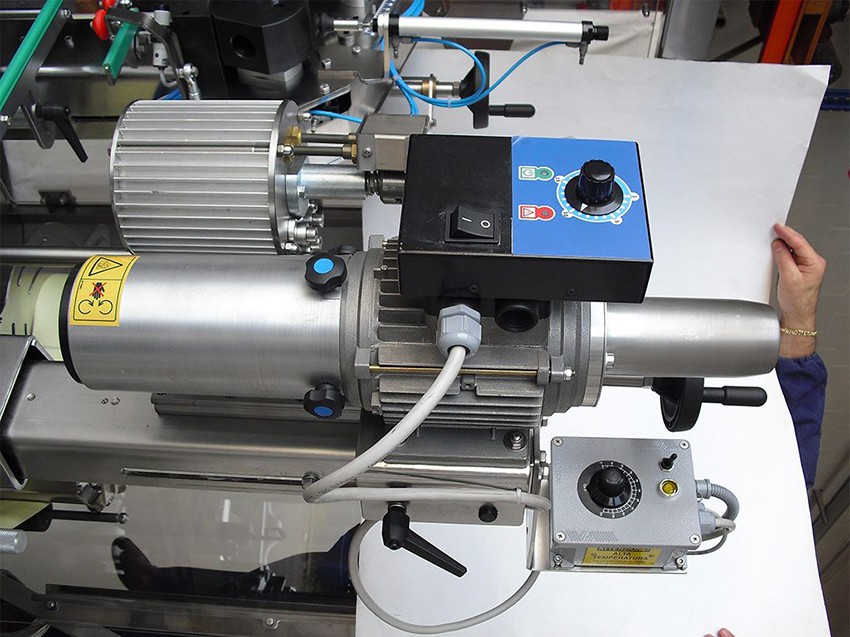

MANUAL LABELLER FOR BENCH (cylindrical, square and shaped formats - 500 bottles/hour)

NITROGEN GENERATOR CHALLENGER SERIES 140 m³ / hour

Manual 120-hole capsule capsule capsule mill between 00 and 4 - 1500 capsules per hour

NITROGEN GENERATOR "AP" 2 Nmc/h

Ozone generator for small/medium enclosed spaces - 80 mc max

Aphrometer for bottles with crown cap diameter 29 mm

Filter system Housing 1 bell 18 cartridges

Air cooled liquid chiller - Super low noise acoustic configuration 375 - 1908 kW

Charcoal Filters for Chemical Fume Hoods without Connections

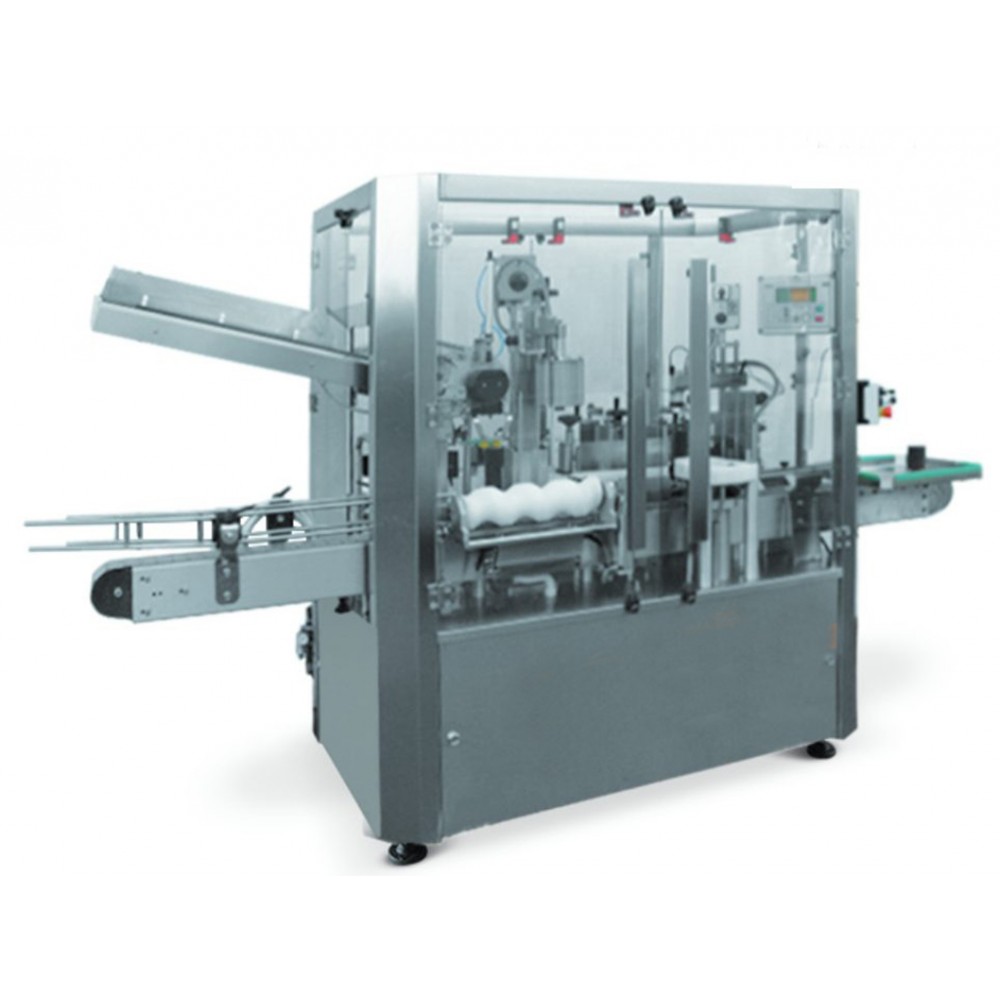

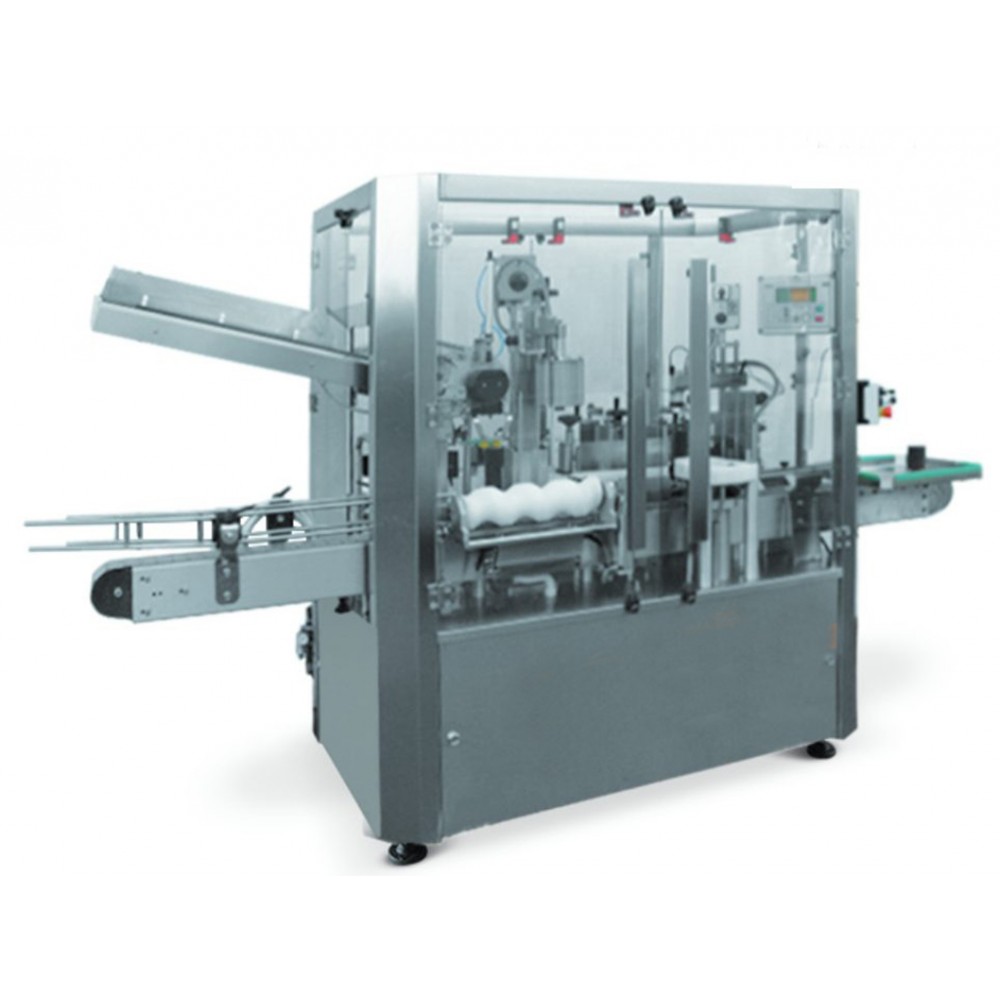

AUTOMATIC LINEAR LABELLER (cylindrical and slightly conical formats - 1500 bottles/hour)