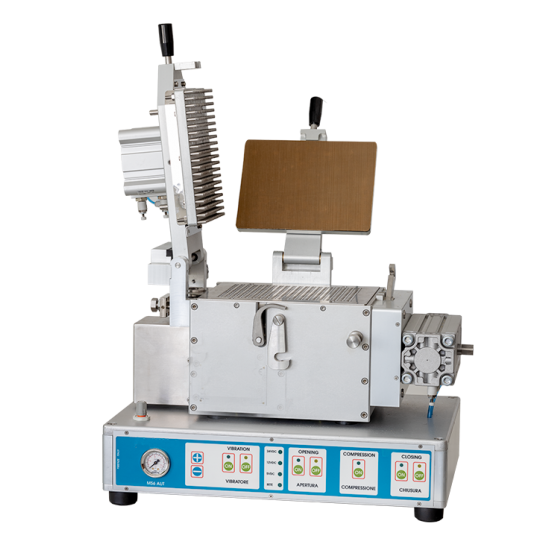

HAAKE™ Ball Drop Viscometer Type C

DOWNLOAD 'MEASURING INSTRUMENTS' LINE CATALOGUE FROM HERE

Download our complete...

Price

€ 5,200