Air cooled liquid chiller - Super low noise acoustic configuration 375 - 1908 kW

.jpg)

Air cooled liquid chiller - Super low noise acoustic configuration 375 - 1908 kW

PRELAFRO - PRELEVATOR for filter housing

Air liquid chiller - Basic acoustic configuration 232 - 1334 kW

Digital liter meter with power supply

Double-diaphragm pneumatic pump 30 - 900 litres / minute

Aphrometer for bottles with Stelvin aluminium cap diameter 87 - height 307 mm

Ozone generator for small/medium enclosed spaces - 80 mc max

Battery-operated digital litre counter

Semi-automatic rinsing and blowing machine 2 and 4 injectors

Digital flowmeter for chemical and corrosive liquids. 20-120 litres/minute

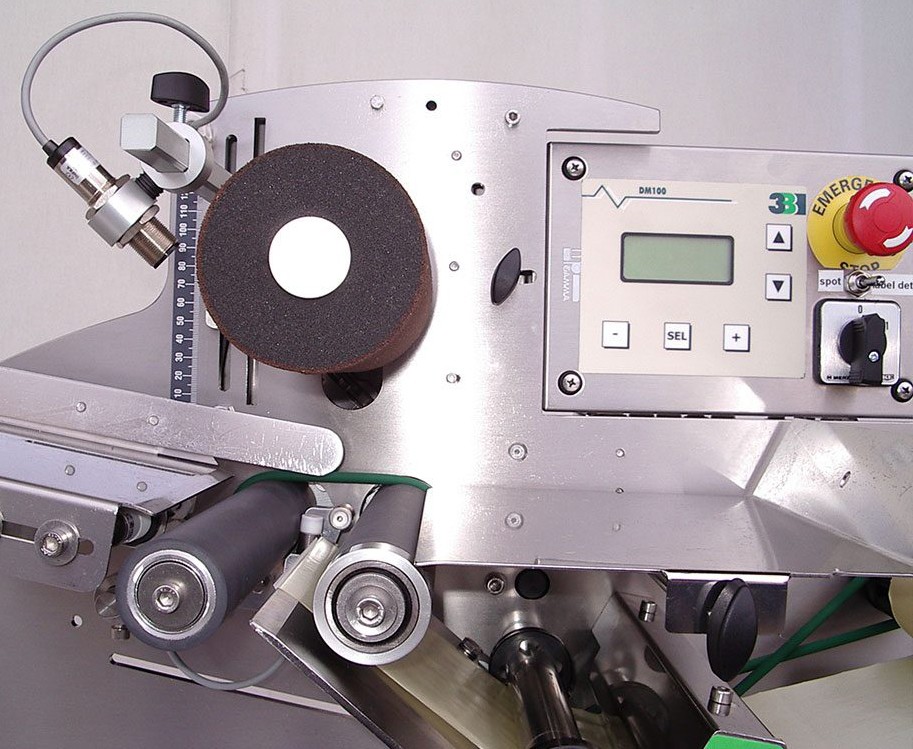

MANUAL Self-Adhesive LABELING MACHINE for round bottles 0.33 - 2 Liters - 150-200 bottles / hour

Stainless steel manual nozzle 80 litres/minute

Filter system Housing 3 bells with 3 cartridges