Volumetric drawer powder feeder

.jpg)

Volumetric drawer powder feeder

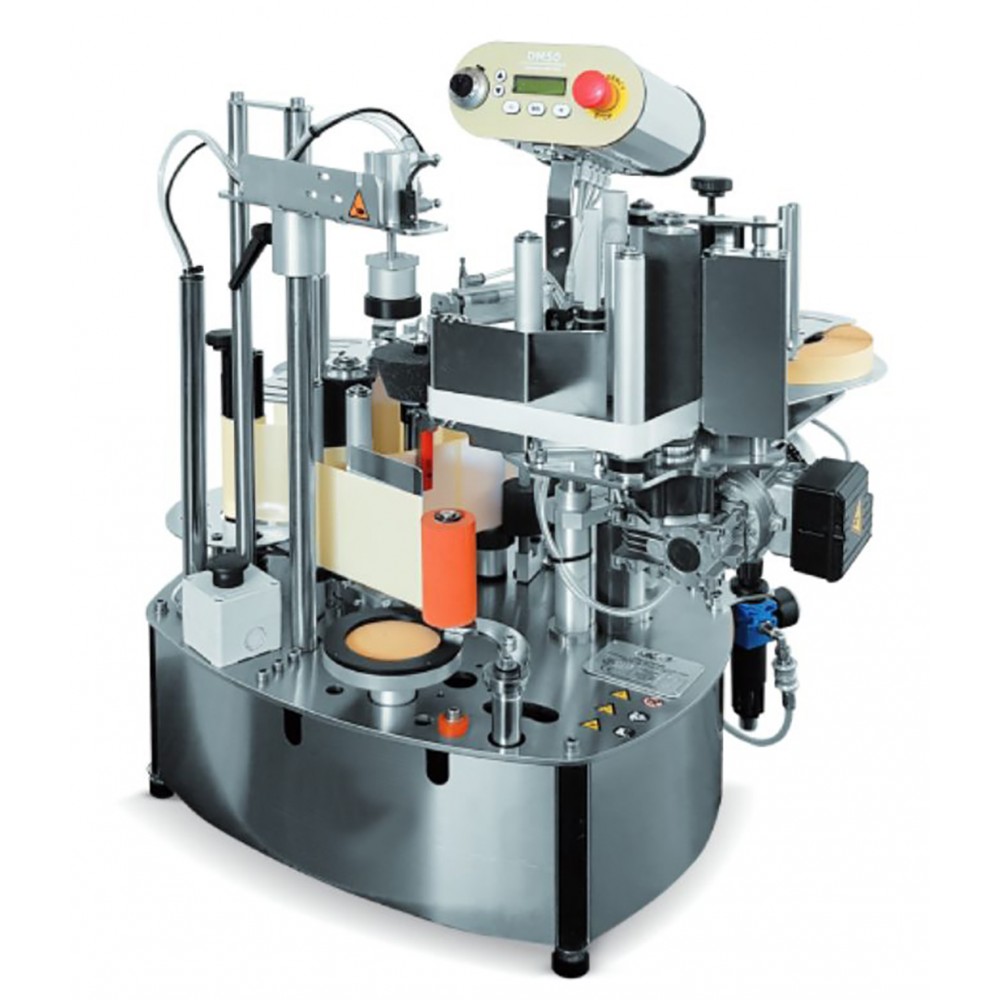

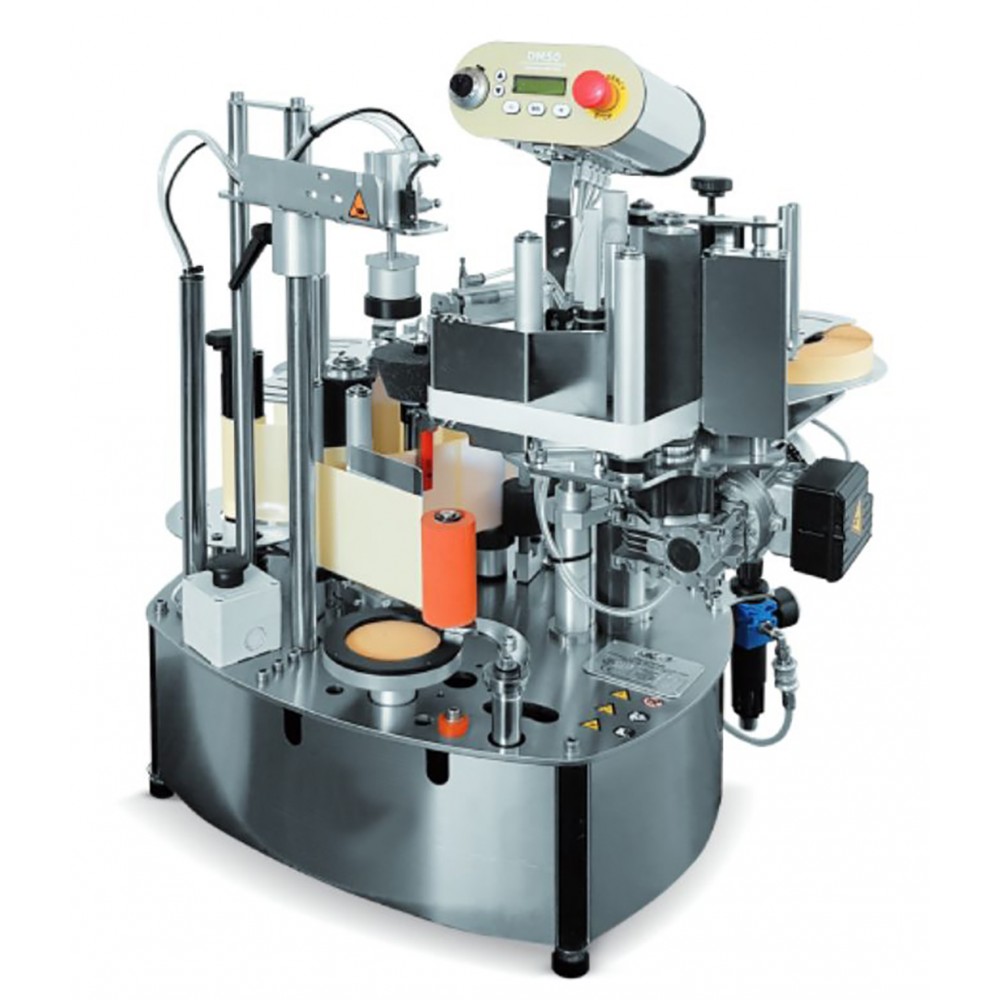

AUTOMATIC LINEAR LABELLER (cylindrical, conical, shaped and special formats - 1300 bottles/hour)

AUTOMATIC LINEAR LABELLER (cylindrical formats - 4000 bottles/hour)

Ozone generator for small/medium enclosed spaces - 80 mc max

Environmental Ozone Generator up to 240 m3 - without OXYGEN CONCENTRATOR

Single-screw floating stator pump 1,400 rpm - 29 quintals/hour - 220V 60 HZ

Optech Stereomicroscopes GZ 808 series

Benchtop tablet press hourly output 3,000/hour

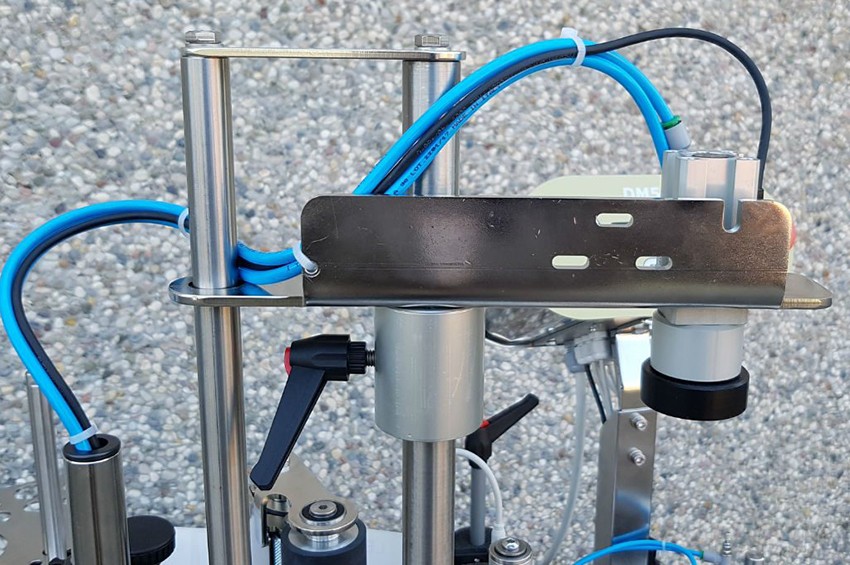

SEMIAUTOMATIC LABELLER FOR BENCH (cylindrical, conical, shaped formats - 700 bottles/hour)

Housing 1 filter system with 12 cartridges

Housing 1 filter system with 8 cartridges

Single-screw floating stator pump 900 rpm 18 hectolitres/hour - THREE-PHASE WITH SWITCH