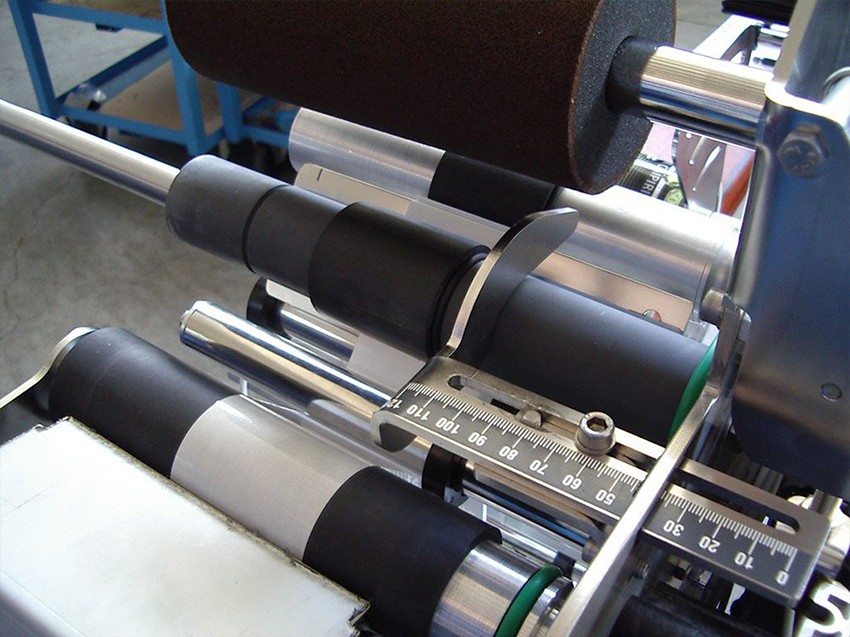

AUTOMATIC LINEAR LABELLER (cylindrical, conical, shaped and special formats - 1300 bottles/hour)

AUTOMATIC LINEAR LABELLER (cylindrical, conical, shaped and special formats - 1300 bottles/hour)

NITROGEN GENERATOR CHALLENGER SERIES 126 m³ / hour

Single screw pump 10 - 2000 rpm 7 minute 2 - 42 hectolitres / hour - INVERTER and THREE-PHASE...

Filter system Housing 1 bell of 3 cartridges

Ozone generator for medium/small closed rooms - 400 m³ max

Two-cylinder vertical volumetric doser

Floating stator progressive cavity pump - 8.5 hectolitres/hour - WITH THREE-PHASE INVERTER AND...

Guardian 7000 magnetic stirrers

Piston pumping unit 10 litres/minute

Single-screw floating stator pump 10 - 2000 rpm - 2-53 hectolitres / hour - THREE-PHASE WITH...

NITROGEN GENERATOR "Mini Gaz" 1 Nmc/h