Water-cooled industrial liquid chiller bi-frequency version kW 60Hz - 12.4 - 191.7 kW

Water-cooled industrial liquid chiller bi-frequency version kW 60Hz - 12.4 - 191.7 kW

Peristaltic pump dosing machine 800 ml/minute

Floating stator progressive cavity pump 10-2000 rpm - 2-53 hectolitres / hour - THREE-PHASE...

Single-screw floating stator pump 1,400 rpm - 6 quintals/hour - WITH INTEGRATED SWITCH

NITROGEN GENERATOR "Mini Gaz" 0,5 Nmc/h

Laboratory instrument for pH measurement

Liquid chiller and water heat pumps – Refrigerator 289-752 kW Thermal 263-686 kW

Turboemulsifier complete with heads 12,500 rpm nominal 10 litres

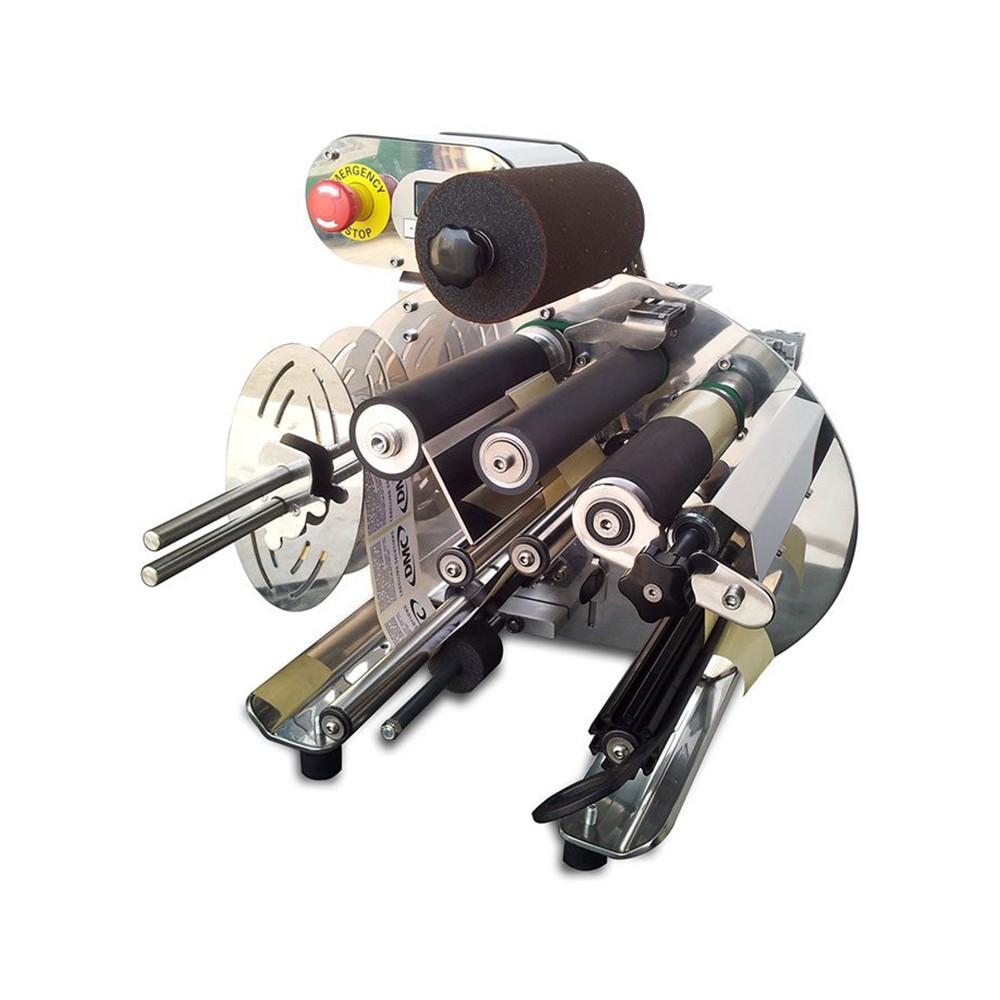

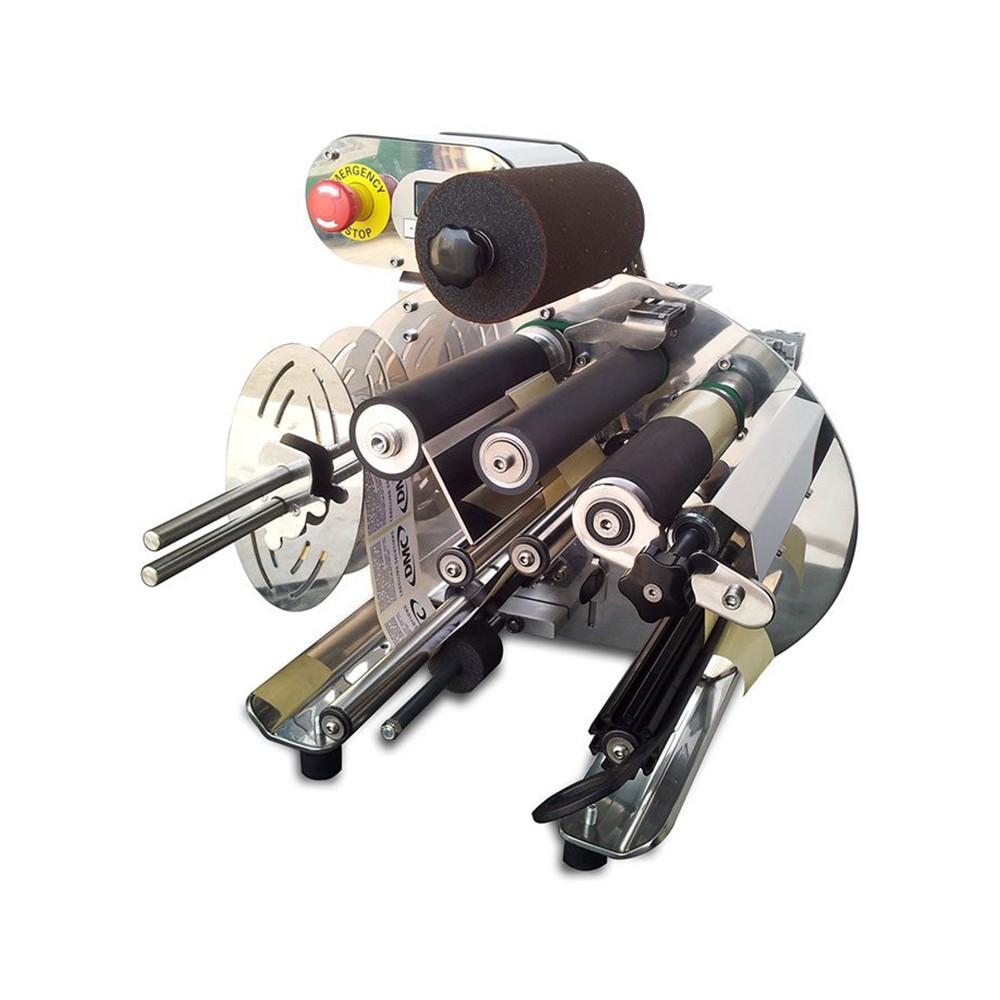

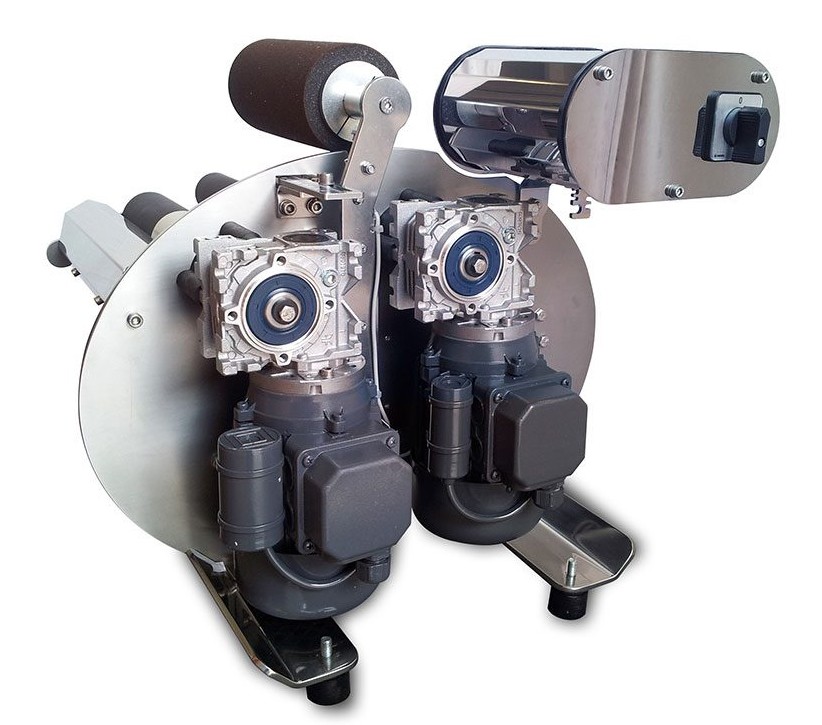

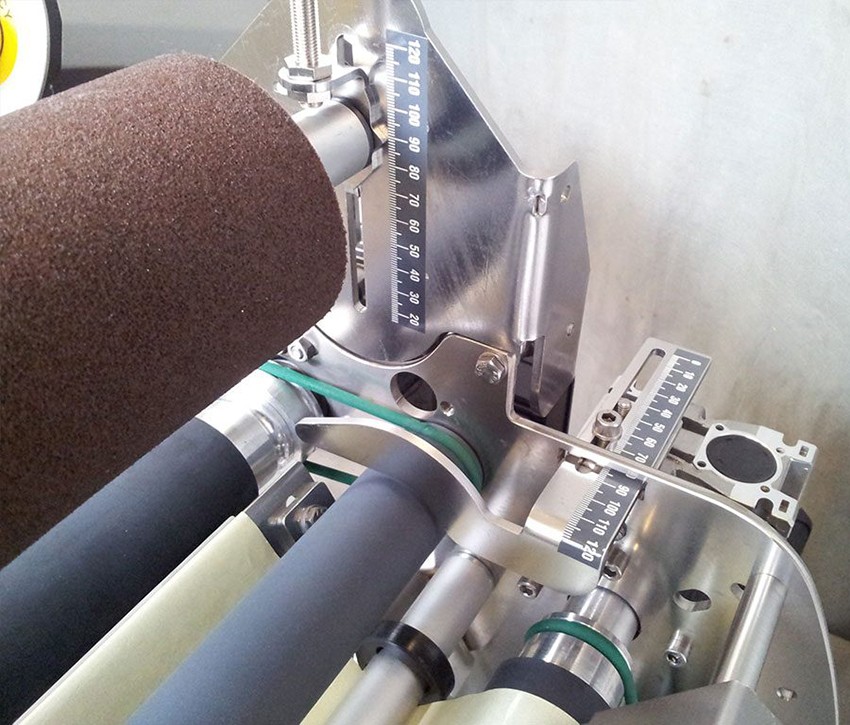

AUTOMATIC LINEAR LABELLER (cylindrical, conical, shaped and special formats - 1300 bottles/hour)

PRELAFRO - PRELEVATOR for autoclave tank - connections 50 garolla, 50 din male with ring nut, 1"...

Digital liter meter with power supply