Description

Benefits:

Innovative finned coil evaporator immersed in the hydraulic tank, characterized by low pressure drops and reduced sensitivity to fouling;

R134a (mod. M03) and R410A (mod. M05-10) refrigerants which, thanks to the best heat exchange properties, allow excellent performance;

Reinforced structure movable by lifting eyebolts;

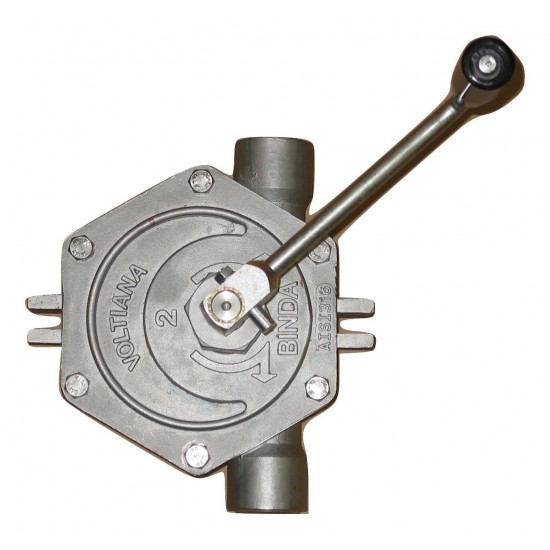

Standard NON FERROUS atmospheric hydraulic circuit;

Atmospheric hydraulic storage tank in polyethylene equipped with visual level indicator, filling cap, drain connections and overflow;

Hydraulic safety by-pass;

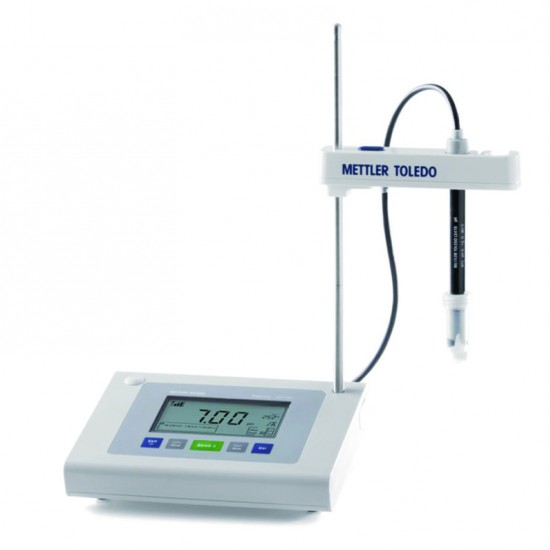

Advanced XR60CX microprocessor control standard on all models;

Clean general alarm contact and digital input for remote ON / OFF;

Ease of installation, use and maintenance;

SEPR HT Tier2 compliant.

Options

Fine temperature regulation version (mod. M08-M10): the outlet process water temperature is regulated with precision (hysteresis ± 0.5 ° C) by means of a hot gas injection solenoid valve, controlled with PID logic;

Version for low water outlet temperature Tw out min = -5 ° C;

P5 pump (mod. M08-M10): non-ferrous peripheral pump with useful head of about 5 barg;

Water level sensor (mod. M08-M10);

Industrial multipolar connector (mod. M08-M10);

Hydraulic sectioning system (mod. M08-M10);

Stainless steel carpentry.

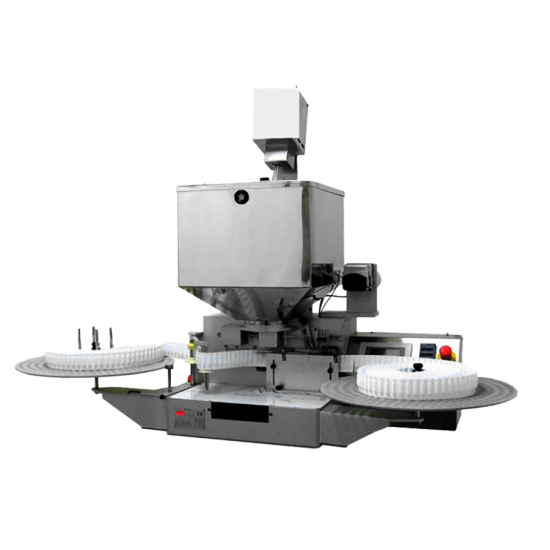

Nominal cooling capacity 1.8 - 4.4 kW; nominal operating conditions: ambient temperature +25 ° C and evaporator IN / OUT water temperature + 20 / + 15 ° C (UNI EN 14511: 2018).

The basic unit includes: polyethylene storage tank, non ferrous peripheral P3 pump, non ferrous hydraulic circuit.

Kits sold separately;

Water filter kit;

External automatic water by-pass kit;

Anti-vibration kit;

Dynamic set point kit;

Wheel kit.