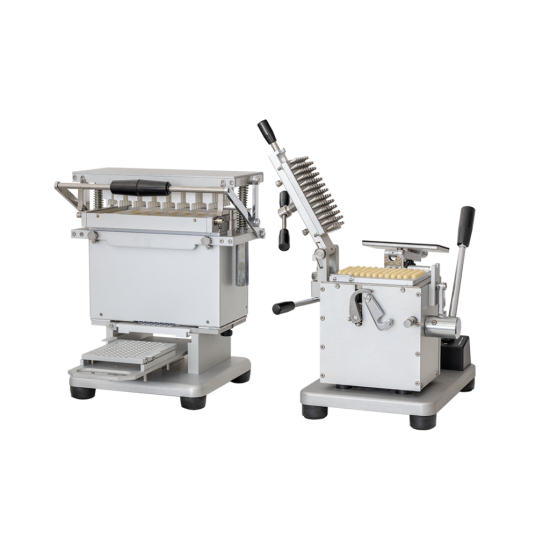

Integrated system of orientator and countertop capsule filler 3500 capsules/hour

Batch quantity: 100

Hourly output: up to 3200

Capsule size: 000 ÷ 5 DB Caps

Power...

Price

€ 10,665