Description

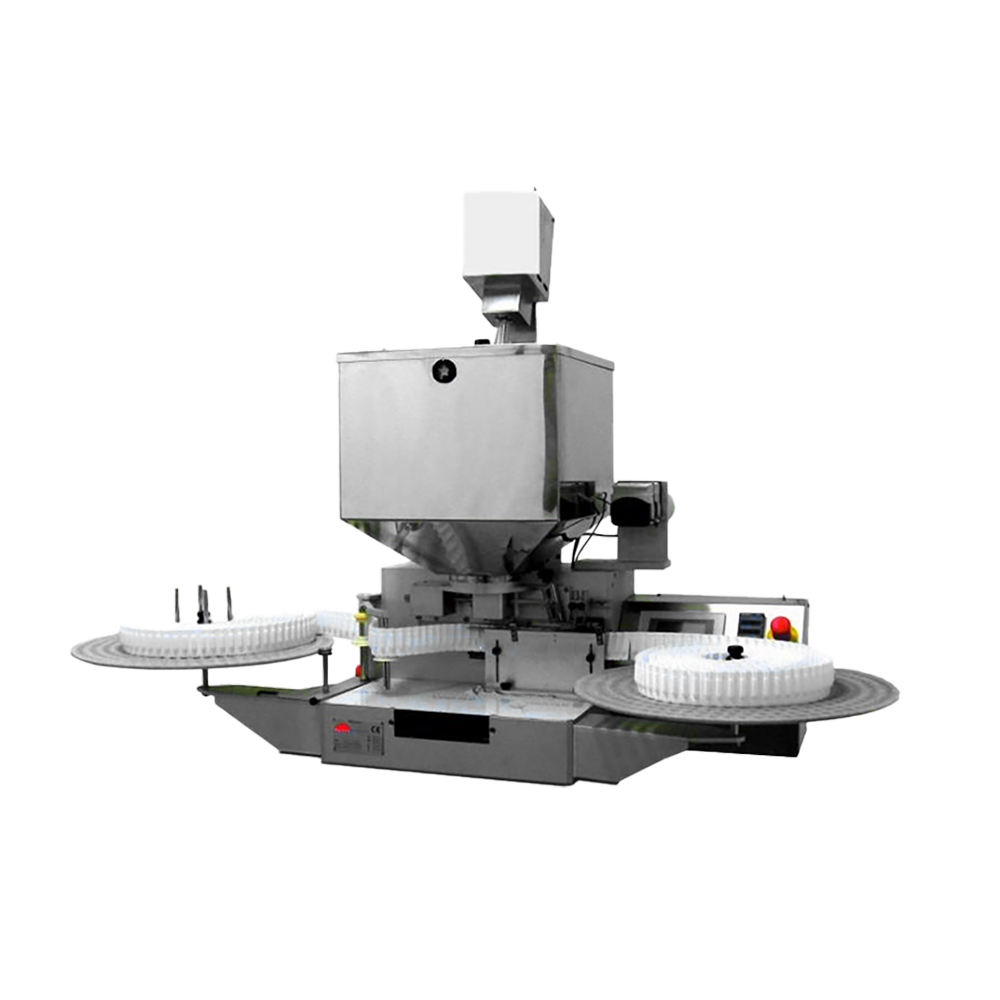

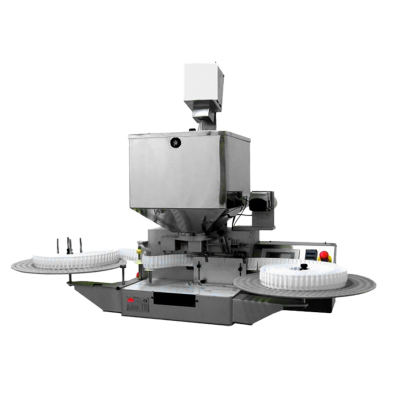

The machine has a dosing unit equipped with two peristaltic pumps for filling liquids and a stainless steel, heated, micrometrically adjustable dosing valve in 1/10 ml increments for the melt of suppositories and ova. The dosing range varies from 5 to 15 ml for liquids, 0 to 3.5 ml and 2 to 5.5 ml for ova and suppositories depending on the dosing unit installed. Hourly output ranges from 3,000 to 6,000 pieces per hour. For ova and suppositories, the machine is equipped with a heated hopper complete with a double-walled, temperature-controlled thermostat and recirculation pump. The hopper has an impeller capable of keeping the melt in constant and homogeneous movement. Both the agitator speed and the temperature of the water contained in the hopper jacket are adjustable. The coils of empty pre-formed honeycombs are placed on a feed disc from which they are dragged and automatically passed under the dosing station. Equally automatically, they are collected on a second disc. For ova and suppositories, the discs with the filled alveoli can be placed in the cooling unit (optional) for rapid cooling. After filling, the coils are placed on the sealing machine. All production parameters are fully programmable via the touch screen and all functions are designed in accordance with GMP standards. Parts in contact with the product are easily inspected and removed and made of stainless steel (AISI 316 L on request) or FDA approved material.